ExtrudAlign™ 2020 Printable

Introducing ExtrudAlign, the ultimate DIY jig for 20mm aluminum extrusion! Print it yourself or get the ready-to-use kit. Perfect for 3D printer builds, CNC projects, and more. Achieve professional accuracy with ease. Drill and tap 20mm V-slot/T-slot with precision. 3D printable jig, available as STL files or a ready-made kit. Accurate, easy, and essential for any extrusion project.

Introducing ExtrudAlign, the ultimate DIY jig for 20mm aluminum extrusion! Print it yourself or get the ready-to-use kit. Perfect for 3D printer builds, CNC projects, and more. Achieve professional accuracy with ease. Drill and tap 20mm V-slot/T-slot with precision. 3D printable jig, available as STL files or a ready-made kit. Accurate, easy, and essential for any extrusion project.

Introducing ExtrudAlign, the ultimate DIY jig for 20mm aluminum extrusion! Print it yourself or get the ready-to-use kit. Perfect for 3D printer builds, CNC projects, and more. Achieve professional accuracy with ease. Drill and tap 20mm V-slot/T-slot with precision. 3D printable jig, available as STL files or a ready-made kit. Accurate, easy, and essential for any extrusion project.

Need to tap the ends of 2020 rails perfectly straight? No problem. Need to drill holes perfectly centered in the slots? No problem. Want to drill a hole centered on the face of 2040 or 4040 rails to run wiring through the channel? No problem. ExtrudAlign™ has you covered. No more dragging your rails to the drill press or fighting with misaligned threads. Bring your tool to the work, not your work to the tool.

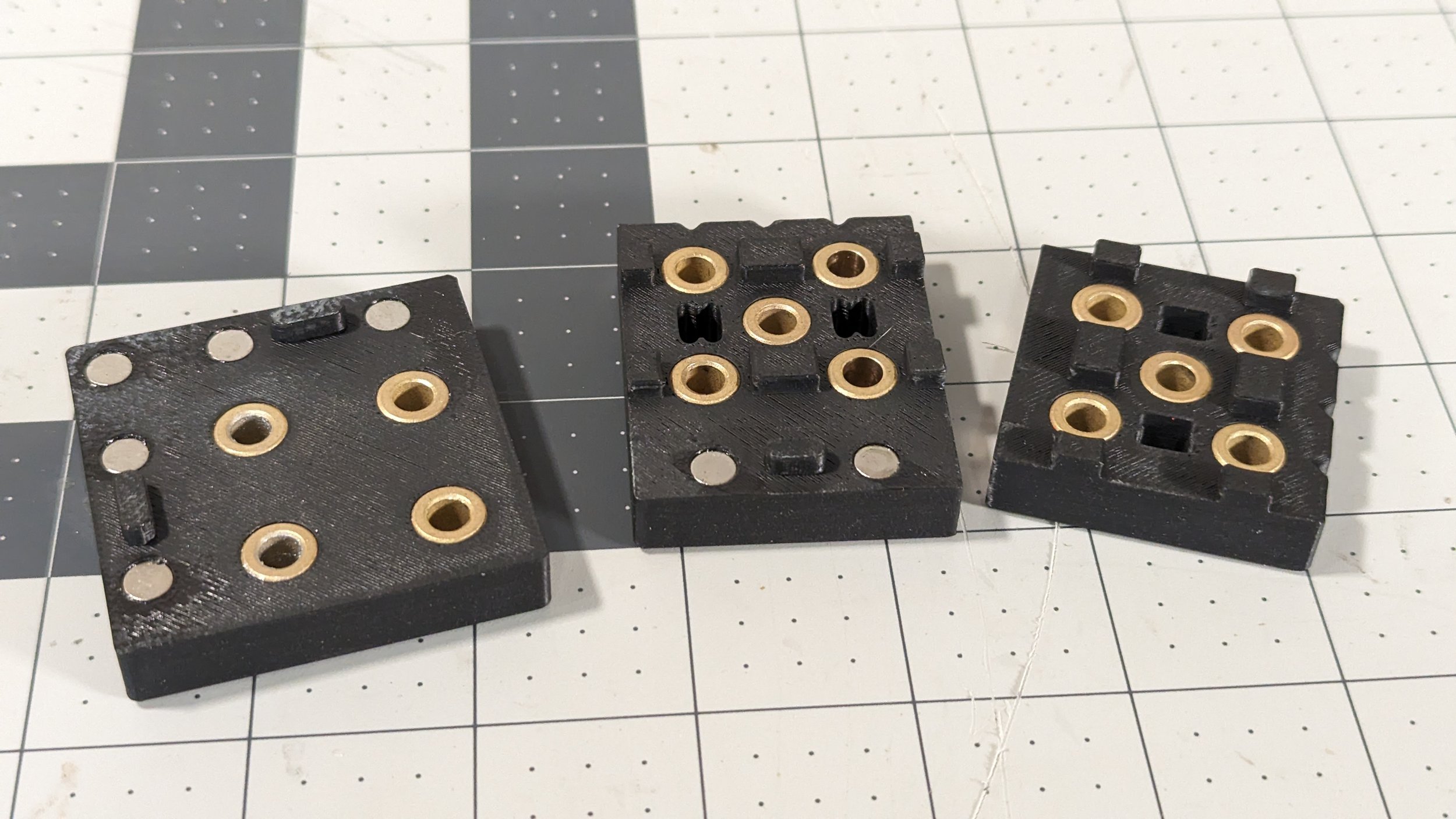

This tap guide perfectly aligns for all four bore channels of 4040, both bore channels of 2040 and the single bore channel of 2020. This will even work for 2060 and 2080 variations. The tap guide plate is detachable allowing you to slide the drill guides along the rail for getting a perfect hole anywhere you need it. This is the last drill and tap guide you will ever need for 20mm profile extruded aluminum.

The drill guide plates have notches at 10mm, 20mm and 10mm centered from their respective edges. These notches align with the center of the corresponding bores. The 10mm notches align with the outer bores while the 20mm aligns with the middle bore. In the middle of the drill guide plates are two “H” shaped windows. These have center indicators that align with the relative 10mm notch and therefore the center of the corresponding bores. Where ever you mark your location to drill, you should be able to quickly and easily place the ExtrudAlign™ drill guides for accurate drilling.

The ExtrudAlign™ parts print quickly - in about an hour on most printers. Additionally you will need 6x2mm magnets and bushings to guide the drill / tap bit. The bushings must be 9mm outer diameter but can be any bore diameter you prefer. We recommend a 5mm bore since that is the typical size of the bore channels in 20mm extruded aluminum. We provide links to recommended sources for these parts and other optional but useful items.

Included

The STL files

A users guide with detailed usage instructions and example uses

A usage license

A document with references to additional sources for the bushings, magnets and other optional related items

Print Settings

First and foremost, we strongly suggest that you have calibrated your printer for dimensional accuracy.

We also recommend you have a filament chosen for which you already have a defined shrinkage percentage. These being establish will produce the best and most accurate results. Due to the inconsistent dimensional accuracy from one 3D printer to the next, we do not guarantee the quality or precision of the final print.

We recommend printing with a 12-18% infill, 5 top and bottom layers and at least 3 perimeter walls for optimal strength. We’ve had great results with PLA and PETG. These filaments have proven more than sufficient for the purpose. You can obviously print with any filament you prefer, but it is not necessary to use ABS, ASA, Nylon or any other filament meant for highly durable prints.